2026 Best Roll Lamination Machine Reviews and Buying Guide?

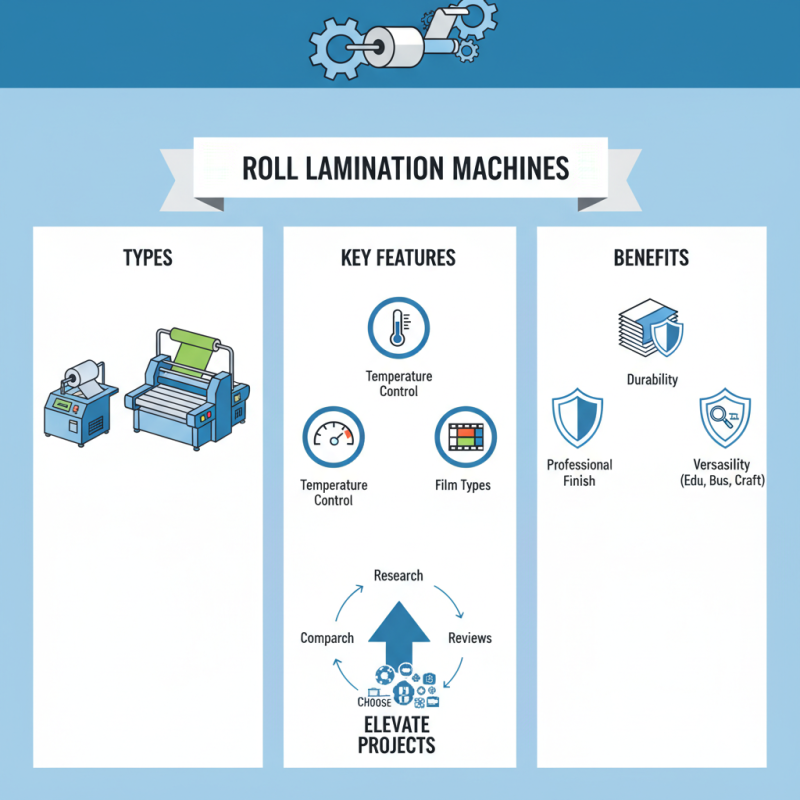

Choosing the right Roll Lamination Machine can transform your projects. These machines provide durability and professional finishes for various materials. Whether you are in education, business, or crafts, finding the best option is essential.

Consider your specific needs. Some machines are compact, ideal for small setups. Others are more robust, designed for high-volume tasks. It can be challenging to figure out what features matter most. For example, temperature control, speed settings, and film types impact results significantly.

Researching and comparing models helps clarify your choices. User reviews often reveal strengths and weaknesses not mentioned in specifications. Ultimately, the right Roll Lamination Machine can enhance your workflow, but it requires careful consideration. Are you ready to elevate your lamination game?

2026 Roll Lamination Machine Market Overview and Trends

The roll lamination machine market in 2026 is constantly evolving. Businesses seek efficient solutions for document protection and visual enhancement. As everyone focuses on durability, the demand for high-quality machines increases. Users desire machines that effectively laminate various materials, enhancing both appearance and longevity.

Emerging trends show a shift toward automation and user-friendly designs. Many machines now offer digital interfaces, making operation much simpler. However, some models are prone to jams and other mechanical issues. While technology advances, users often feel overwhelmed by complications. Finding the right balance between features and ease of use is challenging.

Sustainability is becoming a significant concern. Many businesses look for eco-friendly laminating options. However, not all machines meet these criteria. Some still rely on non-recyclable materials, which can dishearten environmentally conscious users. Buyers must carefully research options to make informed decisions that align with their values.

Key Features to Look for in a Roll Lamination Machine

When choosing a roll lamination machine, key features significantly impact performance. Look for models that offer adjustable temperature and speed controls. This flexibility allows for better results with different materials. Industry reports suggest that machines with these attributes offer a 30% improvement in productivity.

Consider the laminating width. Machines that handle a wider range can accommodate various project sizes. Models with a width of at least 25 inches are commonly recommended. This width allows for handling larger documents effectively. Additionally, an automatic paper feeder can save time and reduce labor costs in high-volume settings.

Tips: Always check for warranty options and customer support. A solid warranty reflects reliability. Pay attention to the maintenance requirements too. Simple upkeep can extend the life of your equipment. Investing in a machine that is easy to operate can boost efficiency and reduce downtime.

Top Brands and Models for Roll Lamination Machines in 2026

When considering roll lamination machines in 2026, a variety of brands and models dominate the market. These machines are not only essential for functionality but also for enhancing product durability. According to recent industry reports, the global laminating machine market is projected to grow by over 5% annually, indicating steady demand.

Top-rated models often feature advanced technologies, such as heat-pressing and cold-laminating options. Many users prefer machines with adjustable speed settings, providing flexibility for different tasks. Research suggests that machines capable of laminating documents up to 12 inches wide rank high among consumer preferences. Yet, with so many options, it’s crucial to evaluate specific needs versus available features.

While some machines excel in performance, they may come with a higher price tag. Reliability is a common concern, as not all models deliver consistent results. Manufacturers also vary in customer support quality. For instance, warranty terms differ widely; some offer better coverage than others. Thus, buyers should weigh the cost against expected durability and service options.

Comparative Analysis: Manual vs. Automatic Roll Lamination Machines

When choosing between manual and automatic roll lamination machines, consider your specific needs. Manual machines require more effort. You control the speed and pressure. This gives you flexibility but can be tiring. Automatic machines handle everything for you. They save time but come with a higher price tag.

Tips: Think about your workflow. If you laminate infrequently, a manual machine may suffice. For businesses, invest in automation. It boosts productivity.

Also, consider space and storage. Manual machines are often smaller. Automatic ones may need dedicated space. Evaluate your workspace before deciding. It's essential to choose wisely; the wrong machine can lead to frustration. Don’t overlook maintenance costs. Some machines require more upkeep than others.

Cost-Benefit Analysis: Investing in a Roll Lamination Machine

Investing in a roll lamination machine can bring significant benefits. These machines help enhance the durability of documents. They provide a protective layer against wear and tear. The initial cost may seem high, but the long-term savings are worth considering. Schools, offices, and print shops can save on frequent reprints.

When evaluating costs, think about the features you need. Basic models may suffice for light use, while heavy-duty ones are better for bulk processing. Assess the frequency of use before making a decision. Weigh the expenses against potential benefits. Will this machine improve your workflow? Consider that carefully.

**Tip:** Always compare different models and their specifications. Look for user reviews to gauge performance.

Another critical factor is maintenance. Some machines may require frequent servicing, adding to overall costs. A cheaper upfront price might lead to higher long-term expenses.

**Tip:** Determine your budget, but also factor in ongoing costs. It’s essential to balance initial investment with future needs.