Advantages of Utilizing the Best Door Jamb Machine for Your Manufacturing Needs

In the rapidly evolving manufacturing industry, the efficiency and precision of production processes are paramount. One often overlooked yet critical piece of equipment is the Door Jamb Machine. According to a recent industry report by Freedonia Group, the demand for machinery that enhances precision and productivity in manufacturing has surged by 7% annually, underscoring the necessity of investing in advanced equipment. The Door Jamb Machine stands out in this context, not only by streamlining the door frame production process but also by reducing long-term maintenance costs, a significant concern highlighted in a Deloitte survey indicating that maintenance expenditures can account for up to 20% of operational costs in manufacturing.

By focusing on the advantages of utilizing the best Door Jamb Machine, manufacturers can ensure superior product quality, effective after-sales service, and ultimately, a robust return on investment.

Maximizing Efficiency: The Role of Door Jamb Machines in Manufacturing

When it comes to manufacturing door jambs, efficiency is key. Utilizing the best door jamb machine can drastically reduce production time and minimize waste. These machines are designed to streamline the process, allowing for quick adjustments and consistent results. This means that manufacturers can meet tight deadlines without compromising on quality, an essential aspect in today's competitive market.

Tip: Regular maintenance of your door jamb machine can significantly enhance its performance. Inspecting the machine for wear and tear, and ensuring that all components are functioning correctly, can prevent unexpected downtimes and costly repairs.

Moreover, modern door jamb machines often come equipped with advanced technology, such as automated measurements and cutting features. This not only speeds up the process but also reduces the likelihood of human error. By adopting such technology, manufacturers can ensure that every piece produced meets the specified standards, leading to higher customer satisfaction.

Tip: Consider training your staff on the latest machine features to maximize productivity. Knowledgeable workers can leverage the machine’s capabilities fully, making adjustments as necessary to optimize production efficiency.

Key Features to Look for in the Best Door Jamb Machines

When choosing the best door jamb machine for your manufacturing needs, several key features should be prioritized to ensure efficiency and accuracy in production. A vital aspect is the machine’s cutting precision; high-quality door jamb machines should provide tolerances of less than 0.5mm to ensure a snug fit for the door. According to a recent report by the National Institute of Standards and Technology, precise manufacturing processes can reduce material wastage by up to 15%, translating to significant cost savings over time.

Another feature to consider is automation capabilities. Machines equipped with advanced sensors and programmable settings can streamline operation, reducing manual labor and increasing throughput. Industry statistics indicate that businesses implementing automated systems can increase their production rates by as much as 30%. This is essential for manufacturers looking to optimize workflow and reduce lead times.

**Tips:** Always assess the machine's ease of use and maintenance requirements. An intuitive interface can significantly reduce training time for operators, while machines designed for easy maintenance can minimize downtime and prolong the lifespan of your investment. Prioritizing these features will lead to enhanced productivity and improved overall efficiency in your manufacturing process.

Cost-Effectiveness: How Quality Machines Save You Money Long-Term

Investing in a high-quality door jamb machine can significantly enhance the efficiency and productivity of your manufacturing processes. One of the key advantages of utilizing a top-tier machine is its cost-effectiveness. While the initial investment may seem substantial, quality machines are engineered for durability and precision, which translates to lower long-term operational costs. They reduce the frequency of repairs and downtime, allowing your business to maintain a steady workflow and meet production deadlines.

Moreover, efficient door jamb machines minimize material waste through precise cuts and accurate measurements. This not only leads to savings on raw materials but also ensures that you are maximizing every dollar spent on production. The combination of reduced waste and enhanced efficiency means that businesses can operate more profitably over time. By making the switch to the best door jamb machinery, manufacturers can achieve a significant return on investment, ensuring that their operations remain financially viable in a competitive market.

Improving Product Quality with Advanced Door Jamb Technology

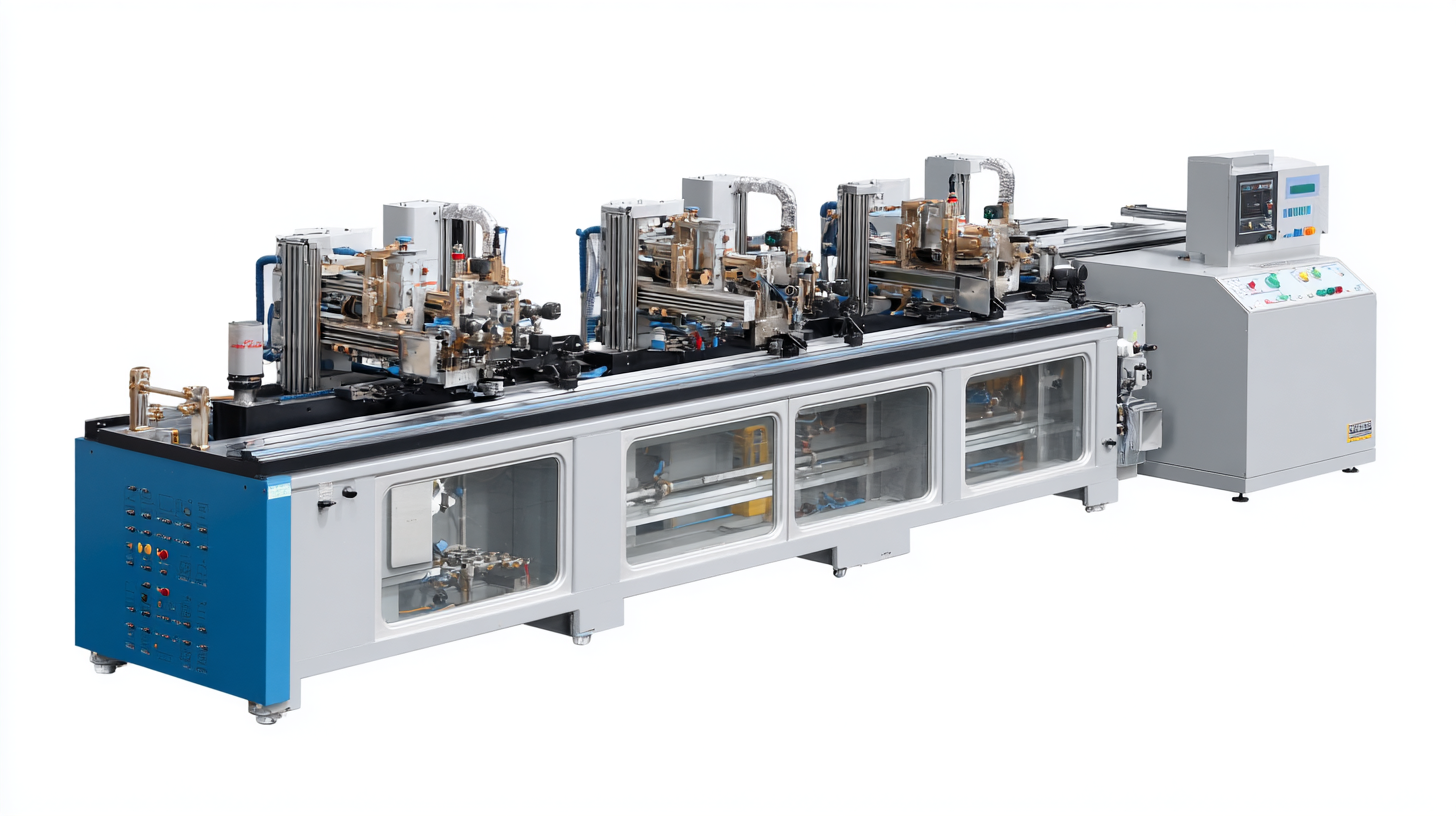

The advancement of door jamb technology has significantly transformed manufacturing processes, particularly in enhancing product quality. Utilizing the best door jamb machines allows manufacturers to achieve precision fabrication, ensuring each component meets stringent quality standards. These machines are equipped with state-of-the-art features that enhance accuracy in cutting, shaping, and assembling door jambs, reducing human error and increasing consistency across products.

Moreover, the integration of advanced technology, such as computer numerical control (CNC) systems, enables manufacturers to optimize their production lines. This innovation not only streamlines the workflow but also facilitates quick adjustments to meet varying specifications, resulting in superior end products. The ability to produce door jambs with exceptional precision directly contributes to improved structural integrity and durability, which are critical factors in customer satisfaction and long-term performance. By investing in the best door jamb machines, manufacturers can elevate their product quality, ultimately gaining a competitive advantage in the market.

Advantages of Utilizing the Best Door Jamb Machine

This chart illustrates the benefits of using advanced door jamb machines in manufacturing processes. The data represents the improvement in various quality metrics.

Enhancing Production Speed: The Impact of Top-Tier Door Jamb Machines on Workflow

In today’s fast-paced manufacturing environment, the efficiency of production processes is paramount. Utilizing top-tier door jamb machines can significantly enhance workflow by dramatically increasing production speed. These advanced machines are designed to handle repetitive tasks with precision and speed, allowing manufacturers to produce door jambs with minimal downtime. As a result, businesses can meet growing demands and improve their bottom line.

Moreover, the integration of high-quality door jamb machines also streamlines the entire manufacturing process. With features such as automated cutting, drilling, and assembly, these machines minimize human error and reduce the time spent on manual labor. This not only boosts overall productivity but also frees up skilled workers to focus on more complex tasks that add greater value to the production line. The combination of speed, efficiency, and accuracy ultimately transforms the way manufacturers approach their workflow, setting new standards in operational excellence.

Advantages of Utilizing the Best Door Jamb Machine for Your Manufacturing Needs - Enhancing Production Speed: The Impact of Top-Tier Door Jamb Machines on Workflow

| Feature | Benefit | Impact on Production Speed | Cost Efficiency |

|---|---|---|---|

| Automation Features | Reduces manual labor | Increases output rate | Low operating costs |

| Precision Engineering | Ensures consistent quality | Minimizes rework time | Reduces waste costs |

| Speed of Operation | Faster setup times | Maximizes productivity | Increases profit margins |

| User-Friendly Interface | Simplifies operation | Reduces training time | Lowers labor costs |

| Durability | Longer lifecycle | Consistent performance | Decreases maintenance expenses |