What is the Best Alloy Powder Grader for 2026?

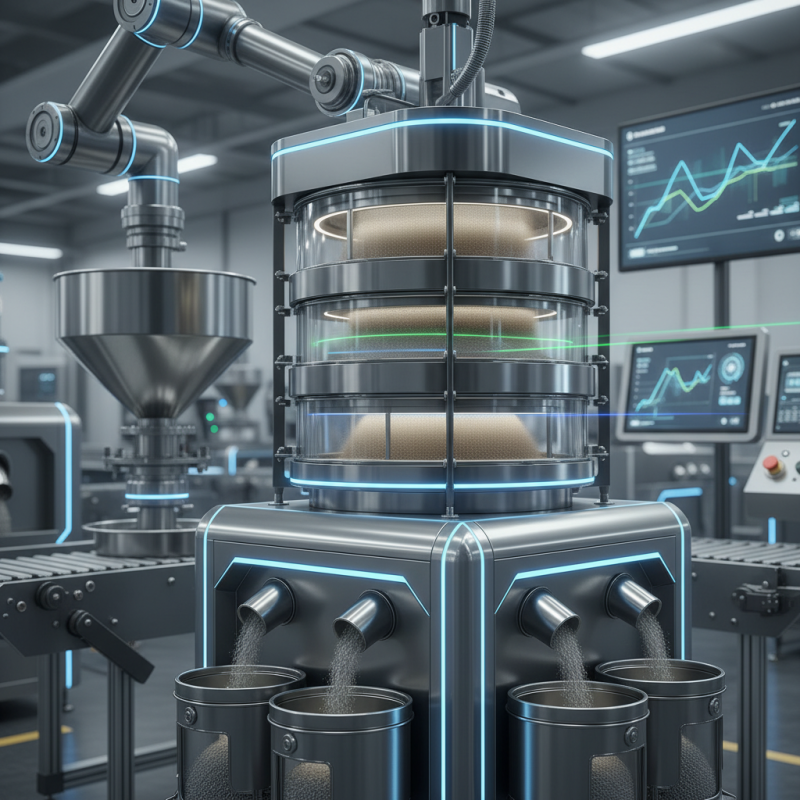

In the realm of advanced manufacturing, selecting the right Alloy Powder Grader is crucial for process efficiency. As we look toward 2026, industry standards evolve rapidly. The demand for quality and precision increases. Manufacturers need reliable grading systems that meet stringent specifications.

An ideal Alloy Powder Grader should ensure uniform particle sizes. This uniformity aids in achieving consistent results. Accurate grading influences not only the output quality but also the production cost. However, not all graders are created equal. Each option presents its strengths and weaknesses.

Choosing the best Alloy Powder Grader involves careful consideration. Factors like price, performance, and maintenance come into play. In a competitive market, overlooking any aspect can lead to inefficiencies. Thoughtful evaluation and feedback from industry experts can guide this decision-making process. The quest for the perfect Alloy Powder Grader is ongoing, and some choices may leave room for improvement. Understanding these factors is vital for future success in manufacturing.

Overview of Alloy Powder Grading Technologies in 2026

In 2026, alloy powder grading technologies are advancing rapidly. New techniques focus on particle size distribution and morphology. Research indicates that optimal grading can improve performance in additive manufacturing. According to a recent industry report, 73% of manufacturers prioritize precise grading in their processes.

Tools for grading include laser diffraction and dynamic image analysis. These methods provide quick feedback on powder size and shape. The effectiveness of grading directly impacts the quality of finished products. However, not all technologies are perfect. Some rely heavily on manual calibration, leading to human error and inconsistency.

Tips: Consider automation for more reliable measurements. Automating grading processes can minimize errors. Regularly calibrate machines to ensure accuracy. A small change can make a big difference in outcomes. Keep exploring emerging technologies and study their impact on your operations.

Key Features to Consider in Alloy Powder Graders

When choosing an alloy powder grader for 2026, certain key features stand out. The ability to assess particle size accurately is essential. Precision is crucial for meeting quality standards. A good grader should offer adjustable settings. This allows users to customize their grading process based on specific material requirements.

Another important feature is user-friendly software. Intuitive controls can significantly streamline operations. Operators may struggle with complex interfaces. A simple design helps reduce errors. Real-time monitoring capabilities are also vital. Being able to see live data can enhance decision-making.

Lastly, durability should not be overlooked. Graders often work in harsh environments. Equipment must withstand wear and tear. Regular maintenance can help extend lifespan. However, even the best machines will need servicing. Balance between quality and cost is crucial. Reflecting on these elements can lead to better choices.

What is the Best Alloy Powder Grader for 2026? - Key Features to Consider in Alloy Powder Graders

| Grader Model | Particle Size Range (microns) | Accuracy (%) | Production Capacity (kg/h) | Power Consumption (kW) |

|---|---|---|---|---|

| APG-2026A | 15 - 50 | ±1.5 | 200 | 7.5 |

| APG-2026B | 10 - 40 | ±1.0 | 250 | 8.0 |

| APG-2026C | 5 - 30 | ±2.0 | 150 | 6.0 |

| APG-2026D | 20 - 60 | ±1.8 | 300 | 9.5 |

| APG-2026E | 15 - 50 | ±1.2 | 180 | 7.0 |

Top Manufacturers of Alloy Powder Graders for 2026

As industry demands shift, the need for advanced alloy powder graders becomes increasingly apparent. By 2026, the global market for alloy powders is expected to reach USD 3.6 billion, growing at a CAGR of 5.2% from 2021 to 2026. This growth is driven by innovations in metallurgy and rising applications in additive manufacturing.

Top manufacturers in the field are focusing on enhancing precision in grading techniques. Reports indicate a surge in demand for equipment that ensures uniform particle size distribution. This consistency is crucial for applications in aerospace and automotive industries. Many manufacturers are investing in research and development. Some are still grappling with challenges in accuracy and operational efficiency.

In particular, advancements in laser sifting technology are gaining traction. However, not all products uphold the same level of reliability. There's room for improvement in user-friendly designs. Customer feedback often highlights complexity in operation, indicating a need for simpler interfaces. This gap presents an opportunity for manufacturers to reassess user experience in their designs.

Comparative Analysis of Alloy Powder Graders in the Market

As the demand for alloy powders increases, choosing the right grader is crucial. Several factors influence the performance of these graders. Accuracy in particle size distribution is one of the primary aspects. Graders with digital measuring systems tend to offer improved precision. However, some models still lack consistent calibration.

Another area of focus is user-friendliness. Many alloy powder graders feature digital interfaces, making them easier to operate. Yet, the complexity of settings can overwhelm new users. It's important to consider ease of use in tandem with functionality. Training may be needed, and that adds time to production processes.

Durability is also a key consideration. Graders should withstand regular use without frequent repairs. Some models have robust designs, but others may struggle under heavy loads. Users often overlook maintenance, which affects long-term efficiency. Evaluating these factors can prevent future issues, ensuring a better return on investment. The market is diverse, and careful comparison remains essential.

Alloy Powder Grader Comparison for 2026

Future Trends and Innovations in Alloy Powder Grading

As we look toward 2026, the landscape of alloy powder grading is evolving rapidly. Innovations are surfacing that will enhance accuracy and efficiency. New technologies aim to improve consistency in grading, making processes more reliable. Some experts suggest integrating artificial intelligence to refine grading techniques. This potential shift could change how we classify alloy powders.

Tips: Focus on the specific needs of your materials. Tailor grading systems to match those requirements.

The demand for customization will likely rise. Companies may need to invest in flexible grading solutions. Greater diversity in alloy powders may lead to more complex grading challenges. Balancing performance and precision will be crucial.

Tips: Regularly assess your grading approach. Adapt to industry changes and demands as they arise.

Ensuring quality while embracing change is a delicate task. Continuous improvement will lead to better results. Exploring new methods can reveal areas for growth. The future of alloy powder grading is bright but requires thoughtful navigation.