What is a Damper Actuator and How Does It Work?

In the realm of HVAC systems, the role of a Damper Actuator is crucial. This device regulates airflow in ventilation systems, ensuring efficiency and comfort. According to a recent report by MarketsandMarkets, the global damper actuator market is expected to grow substantially, reaching $1.2 billion by 2026. Such growth highlights its importance in modern building design.

Expert John Smith, a leader in the HVAC industry, emphasizes, "The effectiveness of a damper actuator is vital for energy efficiency." His words underscore the growing demand for innovative solutions in building management systems. These actuators not only control air movement but also adapt to varying conditions, ensuring optimal performance.

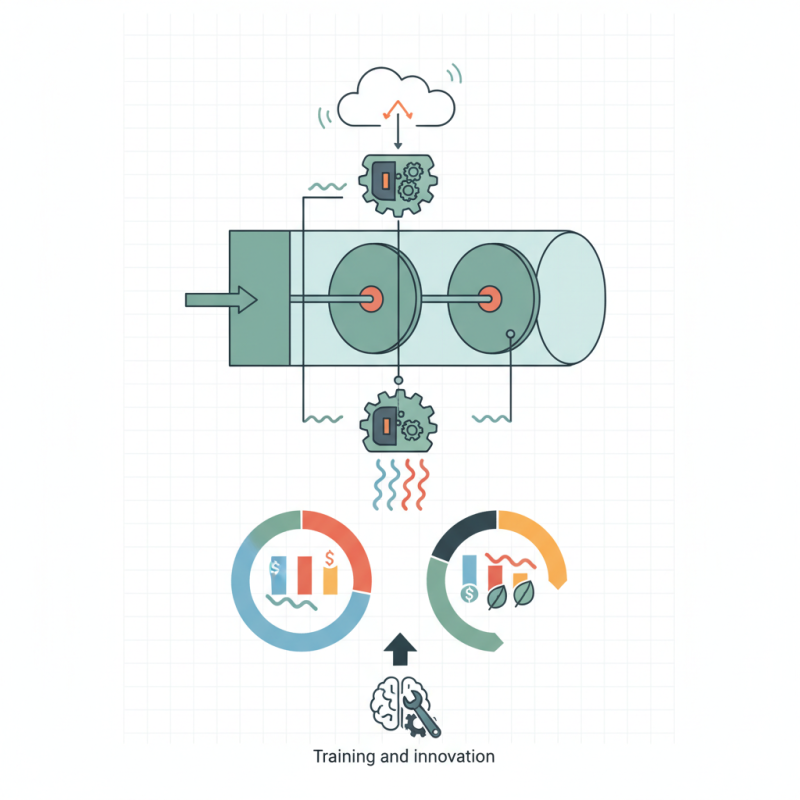

However, the industry faces challenges. Many installations lack proper calibration, leading to inefficiency. Misguided assumptions about airflow control can result in increased energy costs. This highlights the need for continuous training and innovation. Understanding the complexities of Damper Actuators is key for industry professionals aiming to improve system performance.

Definition and Function of a Damper Actuator

A damper actuator is a crucial component in HVAC systems. It controls airflow and temperature regulation in buildings. This device works by adjusting dampers, which are movable plates in air ducts. When the actuator receives a signal, it opens or closes these dampers.

The main function of a damper actuator is to manage air distribution. Proper airflow is essential for energy efficiency and comfort. However, it can sometimes malfunction. This may lead to uneven heating or cooling. Regular maintenance is necessary to ensure optimal functionality.

Understanding how a damper actuator operates can help in troubleshooting issues. It helps in identifying whether the problem lies in the actuator or elsewhere. These devices are not infallible. If they fail, the entire HVAC system can be affected, raising costs and discomfort levels. Being aware of their operation can lead to better care and efficiency in managing indoor climates.

Types of Damper Actuators in HVAC Systems

Damper actuators play a crucial role in HVAC systems. They help regulate airflow by adjusting dampers in ducts. There are several types of damper actuators, each designed for specific applications. Mechanical actuators are simple and reliable. They rely on physical movement to open or close dampers. These are often used in smaller systems or residential applications.

Electric actuators are more common in larger buildings. They provide greater precision and control. These actuators can be modulating or on/off types. Modulating actuators allow for variable positioning of dampers. This helps maintain a consistent airflow based on system demands. On/off actuators, however, simply open or close the damper.

Pneumatic actuators work differently. They use air pressure to control damper position. These can be a good choice for environments where electricity is not ideal. The choice of actuator impacts efficiency and performance. Selecting the right type requires careful consideration of system needs. Not all systems will benefit from the same actuator. Balancing cost with functionality often presents challenges.

Operational Mechanism of Damper Actuators

Damper actuators play a crucial role in controlling airflow within HVAC systems. They regulate the opening and closing of dampers, which direct air in various systems. The operational mechanism begins with an input signal from the control system. This signal triggers the actuator to adjust the damper position. Typically, they utilize electric, pneumatic, or hydraulic power.

Research indicates that appropriately functioning damper actuators can improve energy efficiency by 20-30%. This is significant for both residential and commercial applications. They adjust quickly, responding to changes in room temperature or air quality. However, challenges arise with actuator calibration and maintenance. Faulty actuators can lead to improper airflow distribution, risking system performance.

Moreover, high operational demands often stress these components. As a result, their lifespan might decrease unexpectedly. Regular inspections are essential, but not always performed. Proper training can enhance the understanding of these devices. Many professionals overlook the need for detailed checks. This oversight can lead to costly repairs later. Ultimately, the efficiency and reliability of HVAC systems hinge on the effective operation of damper actuators.

Applications of Damper Actuators in Various Industries

Damper actuators play a crucial role across various industries. In HVAC systems, they regulate airflow and maintain climate control efficiently. According to industry reports, effective airflow management can reduce energy consumption by up to 30%. This highlights the importance of optimizing damper actuators in our daily environments.

In the automotive sector, damper actuators control air intake and exhaust. They help maintain engine performance and improve fuel efficiency. A recent study found vehicles equipped with advanced damper actuators achieve up to 15% better fuel economy. This technology is integral for meeting stringent emission standards globally.

Tips for optimizing damper actuators include regular maintenance checks. Ensuring they are clean and functioning can enhance their lifespan. Also, consider the material used in actuators. It significantly impacts their performance and durability.

In manufacturing, these devices control air and gas flows in processes. They help maintain safety and efficiency. However, improper calibration can lead to inconsistent operations. It's vital to monitor them closely to avoid costly downtimes. Proper installation procedures are also essential to ensure they perform well.

Maintenance and Troubleshooting of Damper Actuators

Damper actuators are crucial for regulating airflow in HVAC systems. Proper maintenance is vital for their longevity and performance. Regular inspections can help identify issues early. Pay attention to unusual noises or inconsistent operation, as these may signal problems.

Cleaning is essential. Dust and debris can build up and impede movement. Use a soft cloth to wipe down the actuator and surrounding areas. If the actuator operates slowly, it might need lubrication. However, be cautious. Over-lubricating can cause further complications.

During troubleshooting, check the power supply first. A simple loose connection can lead to failures. If the actuator does not respond, it may require replacement. Remember to document the issues encountered. This information can guide future maintenance efforts. Each episode offers a learning opportunity, refining the upkeep process.

What is a Damper Actuator and How Does It Work? - Maintenance and Troubleshooting of Damper Actuators

| Feature | Description | Common Issues | Maintenance Tips |

|---|---|---|---|

| Type | Electric, Pneumatic, or Hydraulic | Sticking | Regular lubrication to prevent sticking |

| Function | Controls airflow by opening or closing dampers | Inconsistent operation | Check electrical connections and power supply |

| Components | Motor, linkage, and actuator | Motor failure | Inspect motor for wear and replace if needed |

| Installation Location | HVAC systems, exhaust systems | Improper installation leading to operational issues | Ensure correct alignment during installation |

| Control System | Can be manual or automatic | Signal interference | Check control signal and address any interference |