How to Effectively Select Used Door Shop Equipment for Your Business Needs

Selecting the right used door shop equipment is a critical step for any business looking to enhance operational efficiency while staying within budget. The market is flooded with various options, making it essential to approach the purchasing process with clear guidelines and a strategic mindset. Understanding your specific needs, evaluating the condition and functionality of equipment, and considering compatibility with existing processes are key elements to ensure that your investment pays off. Additionally, being aware of reputable suppliers and the potential for negotiating prices can significantly impact your purchasing decision.

This guide aims to provide valuable insights and practical tips on effectively selecting used door shop equipment, empowering you to make informed choices that not only meet your current business requirements but also support future growth and innovation.

Identifying Your Specific Equipment Requirements for Door Shop Operations

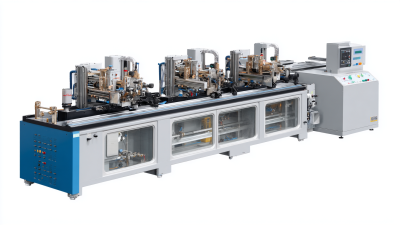

When selecting used door shop equipment, the first step is to identify your specific operational needs. Consider the types of doors you will be working with, as different materials and designs require various tools and machinery. For instance, if your focus is on solid wood doors, you may need equipment that can handle heavy-duty cutting and shaping, such as table saws and thickness planers. Alternatively, for steel or fiberglass doors, welding equipment and specialized hardware may be essential. It's crucial to create a comprehensive list of the equipment that matches your production goals and the volume of work you anticipate.

Next, assess the condition and specifications of the used equipment. Check for signs of wear, maintenance records, and functionality to ensure that the equipment can meet your workload without frequent breakdowns. Engage with previous owners to learn about the equipment's history and any modifications that may have been made. Taking the time to evaluate each piece of machinery will help you minimize future repair costs and maximize productivity. By aligning your equipment selection with your specific requirements and operational scale, you can ensure that your door shop is well-equipped to succeed in a competitive market.

Evaluating the Condition and Reliability of Used Door Shop Equipment

When selecting used door shop equipment, evaluating its condition and reliability is paramount to ensure operational efficiency and safety. First and foremost, a thorough inspection of the equipment is essential. Look for signs of wear and tear, such as rust, dents, or unusual noises during operation. Additionally, reviewing maintenance records can provide insights into the equipment's history and reliability. A machine that has been well-maintained is more likely to perform consistently, while equipment with a history of frequent repairs might lead to unexpected downtime, adversely affecting your business.

Moreover, it's beneficial to understand the technology and features of the equipment in relation to your specific needs. For instance, ensuring compatibility with existing systems and assessing energy efficiency can significantly influence long-term operational costs. Utilizing tools that are designed for evaluating performance and condition, such as diagnostic testing devices, can provide a more comprehensive assessment. By adopting a systematic approach to evaluating used door shop equipment, businesses can make informed decisions that not only meet immediate needs but also align with future growth and sustainability objectives.

How to Effectively Select Used Door Shop Equipment for Your Business Needs - Evaluating the Condition and Reliability of Used Door Shop Equipment

| Equipment Type | Condition | Reliability Rating | Price ($) | Warranty Period (Months) |

|---|---|---|---|---|

| Table Saw | Good | 8/10 | 1,200 | 12 |

| Router | Fair | 6/10 | 250 | 6 |

| Band Saw | Excellent | 9/10 | 1,500 | 24 |

| Planer | Good | 7/10 | 900 | 18 |

| Drill Press | Very Good | 8/10 | 600 | 12 |

Understanding the Importance of Brand and Model Reputation in Used Equipment

When selecting used door shop equipment, the importance of brand and model reputation cannot be overstated. Industry reports indicate that approximately 70% of businesses opt for well-known brands due to their reliability and the availability of support services. This trend highlights the correlation between brand reputation and long-term operational success. Reputable brands often come with established market presence, ensuring that parts and service support are readily available, which is crucial for maintenance and longevity of the equipment.

Furthermore, models that have positive reviews and a strong track record tend to hold their value better over time. According to a report by the Industrial Equipment Research Institute, used equipment from respected brands can maintain upwards of 50-70% of their initial value after several years, compared to lesser-known brands that can depreciate substantially faster. This financial advantage emphasizes the value in investing in recognized brands, as they not only meet immediate operational needs but also contribute positively to the overall financial health of a business when it comes time for an upgrade or closure.

Assessing Cost vs. Value: Making Smart Financial Decisions

When selecting used door shop equipment for your business,

assessing cost versus value becomes imperative.

A lower price may seem attractive, but it is essential to evaluate whether the equipment’s condition and performance justify that cost.

Investigate the history of the equipment, including its previous usage and maintenance records.

This approach helps prevent unexpected expenses that can arise from purchasing equipment that might require extensive repairs or replacements shortly after acquisition.

Furthermore, consider the long-term implications of your purchase. Investing in higher-quality equipment,

even if it carries a higher upfront cost, can lead to greater efficiency and reliability over time.

Conduct thorough research to compare similar equipment options and understand market prices.

This informed perspective allows you to identify the best possible value, balancing initial expenditures with future savings in maintenance and downtime costs.

Ultimately, making smart financial decisions involves looking beyond the purchase price and assessing overall value in relation to

operational needs and business growth.

Tips for Negotiate Prices When Buying Used Door Shop Equipment

When negotiating prices for used door shop equipment, it's crucial to approach discussions with a clear understanding of market values and a strategic mindset. According to a report by IBISWorld, the door manufacturing industry has been experiencing moderate growth, with an annual market size of approximately $25 billion in the U.S. This insight helps establish benchmarks for pricing, allowing buyers to differentiate between equipment that is fairly priced and those that are overpriced.

Effective negotiation should begin with thorough research. Buyers can utilize resources such as industry publications and online marketplaces to compare prices. A recent survey published by the National Association of Manufacturers highlighted that 72% of manufacturers reported gaining significant savings through effective negotiation tactics, such as leveraging multiple quotes and assessing the condition and history of the equipment. Additionally, being prepared to walk away can often give you the upper hand, pushing sellers to reconsider their price in order to make a sale.

Related Posts

-

Future Trends in Door Shop Equipment Market Analysis for Global Buyers by 2025

-

Navigating Export and Import Certifications for Best Interior Door Machines in Global Trade

-

Top 10 Door Machine Manufacturers from China at the 137th Canton Fair

-

Unlocking the Secrets of High Efficiency Door Machines and How to Maximize Their Performance

-

Comprehensive Insights into Frame Assembly Machines for Global Buyers

-

Advantages of Utilizing the Best Door Jamb Machine for Your Manufacturing Needs