Unlocking Efficiency: The Ultimate Guide to Door Manufacturing Equipment for Modern Factories

In today's fast-paced industrial landscape, the efficiency of manufacturing processes is paramount, particularly in the door manufacturing industry, which is projected to grow significantly, with a market value expected to reach USD 85.7 billion by 2026 (Global Market Insights). With the advancement of technology, modern factories are increasingly reliant on sophisticated Door Manufacturing Equipment that streamlines production, improves precision, and enhances overall output. According to a report by MarketsandMarkets, adopting automated door manufacturing solutions can reduce production time by up to 30%, enabling manufacturers to respond more swiftly to market demands. This guide aims to explore various types of Door Manufacturing Equipment available to modern factories, highlighting their capabilities and potential impact on productivity and efficiency in this vital sector.

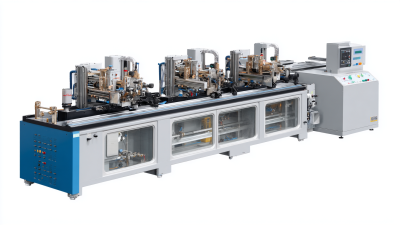

Essential Door Manufacturing Equipment: A Comprehensive Overview

In the realm of door manufacturing, having the right equipment is paramount to achieving efficiency and quality in production. Recent industry reports indicate that the global door manufacturing equipment market is expected to reach $4.5 billion by 2025, growing at a CAGR of 5.6% from 2021. This growth underscores the increasing importance of advanced machinery that can deliver precision and speed to meet rising consumer demands. Key equipment includes CNC machines, which allow for intricate designs and reduce material waste, enhancing overall productivity.

Moreover, automation technologies are reshaping the landscape of door manufacturing. According to a 2022 survey by the Association of Woodworking and Furniture Suppliers, 67% of manufacturers reported that investing in automated systems improved their production rates significantly. Automated cutting and assembly lines not only speed up the manufacturing process but also minimize human error, leading to higher quality finished products. As manufacturers look to streamline operations, the integration of these essential technologies is crucial for staying competitive in today's fast-paced market.

Modern Technologies Transforming Door Production Efficiency

In the evolving landscape of manufacturing, modern technologies are reshaping door production efficiency like never before. Features such as automation and robotics play a crucial role in streamlining processes that once took hours to complete. Automated cutting machines and CNC (Computer Numerical Control) routers allow factories to achieve greater precision while significantly reducing labor costs. As a result, manufacturers can produce high-quality doors faster, meeting the increasing market demands.

Moreover, the integration of IoT (Internet of Things) in manufacturing processes offers real-time data analytics, enhancing decision-making capabilities. Smart sensors monitor equipment performance and maintenance needs, minimizing downtime and optimizing production schedules. With the ability to track inventory and supply chain logistics seamlessly, manufacturers can ensure that they operate at peak efficiency, ultimately leading to a more sustainable and profitable operation. This transformation is not merely a trend; it is becoming a standard for modern factories looking to stay competitive in the fast-paced building and construction industry.

Key Features to Look for in High-Performance Door Machinery

When selecting high-performance door machinery for modern factories, it's essential to focus on key features that enhance efficiency and productivity. One of the most critical aspects is the machine's automation capabilities. Advanced machinery with automated controls can significantly reduce manual input, leading to quicker production cycles and minimizing human error. Look for equipment that features programmable settings, allowing for easy adjustments to accommodate various door designs and materials.

In addition to automation, consider the versatility of the machinery. High-performance door manufacturing equipment should handle a wide range of materials, from solid wood to aluminum composites. This flexibility can streamline your production process, enabling your factory to respond to diverse customer demands without the need for multiple machines.

Tip: Regular maintenance of your machinery is vital for maintaining performance. Schedule routine check-ups to ensure all components function efficiently. Another tip is to invest in machines that offer real-time monitoring, which can help in identifying potential issues before they escalate, ensuring continuous production without costly downtimes.

Streamlining Your Workflow: Integrated Systems for Door Manufacturing

In today’s rapidly evolving manufacturing landscape, integrating advanced systems is crucial for enhancing workflow efficiency in door manufacturing. Modern factories are now leveraging integrated equipment that combines various processes, reducing the need for manual intervention and minimizing the risk of errors. By implementing automated systems, manufacturers can streamline their operations, ensuring that every aspect of door production—cutting, assembling, and finishing—is seamlessly connected. This level of integration not only speeds up production times but also optimizes resource allocation, ultimately leading to higher output with lower operational costs.

Moreover, integrated systems provide real-time data analytics, allowing manufacturers to track performance metrics and identify bottlenecks in the workflow. With this insight, businesses can make informed decisions to improve processes and adapt to changing market demands. The shift toward integrated production lines also promotes flexibility, enabling factories to quickly switch between different door designs without extensive downtime. As the door manufacturing industry continues to embrace these innovations, the focus on integrated systems will undoubtedly be a key driver in achieving operational excellence and staying competitive in the market.

Unlocking Efficiency: The Ultimate Guide to Door Manufacturing Equipment for Modern Factories

| Equipment Type | Function | Efficiency Benefits | Integration Capabilities |

|---|---|---|---|

| CNC Router | Precision cutting of door materials | High accuracy and reduced waste | Can integrate with CAD systems |

| Edge Banding Machine | Applying edge banding to door panels | Improves aesthetics and durability | Compatible with inventory management systems |

| Sanding Machine | Smoothing surfaces of door materials | Ensures surface finish quality | Easily integrates with finishing lines |

| Vertical Panel Saw | Vertical cutting of large panels | Maximizes material usage | Connects with production scheduling software |

| Automated Assembly Line | Assembling door components | Increases throughput and consistency | Integrates with ERP systems |

Maintenance Tips for Ensuring Longevity of Production Equipment

Maintaining production equipment is essential for manufacturers aiming to maximize efficiency and prolong service life. Regular maintenance routines, including inspections and cleanings, ensure that machinery operates at peak performance. For example, lubricating moving parts prevents friction and wear, thereby reducing downtime and costly repairs. Utilizing a maintenance schedule tailored to each piece of equipment can also help identify potential issues before they escalate, saving time and resources.

In addition to routine maintenance, operator training plays a crucial role in equipment longevity. When staff understand the proper use and care of machinery, they can avoid common mistakes that lead to premature wear or breakdowns. Empowering operators with knowledge about specific maintenance tasks and safety guidelines contributes to a culture of responsibility that enhances overall productivity. Investing in both maintenance practices and operator education is a smart strategy for modern factories looking to optimize their door manufacturing processes.

Related Posts

-

Exploring Industry Solutions with Door Lite Cut Out Machine What It Brings to Your Production Line

-

How to Choose the Best Door Manufacturing Equipment for Your Production Needs

-

Advantages of Utilizing the Best Door Jamb Machine for Your Manufacturing Needs

-

Mastering the Best Door Shop Equipment for Maximum Efficiency

-

Exploring the Unique Features and Applications of Door Lite Cutters: A Comprehensive Buying Guide

-

Ultimate Guide to Comparing Casing Machines for Optimal Performance