Comprehensive Insights into Frame Assembly Machines for Global Buyers

In recent years, the manufacturing landscape has been rapidly evolving, with automation technologies gaining prominence across various industries. According to a report by MarketsandMarkets, the global assembly machine market is expected to grow from $25 billion in 2021 to $39 billion by 2026, reflecting an average annual growth rate of 9.5%. This surge in demand is driven by the increasing need for efficiency and precision in manufacturing processes. Within this context, the Frame Assembly Machine has emerged as a critical component, facilitating the systematic assembly of frames for a wide range of products, from automobiles to electronic devices.

The Frame Assembly Machine not only enhances production speed but also significantly reduces labor costs and minimizes errors, making it an indispensable asset for manufacturers worldwide. A study by Grand View Research highlights that advancements in automation and robotics are set to reshape assembly line functionalities, paving the way for more advanced frame assembly solutions. As global buyers seek to optimize their manufacturing capabilities, understanding the intricacies of Frame Assembly Machines becomes essential. This blog aims to provide comprehensive insights into these machines, addressing their features, benefits, and the factors influencing their adoption in the competitive manufacturing environment.

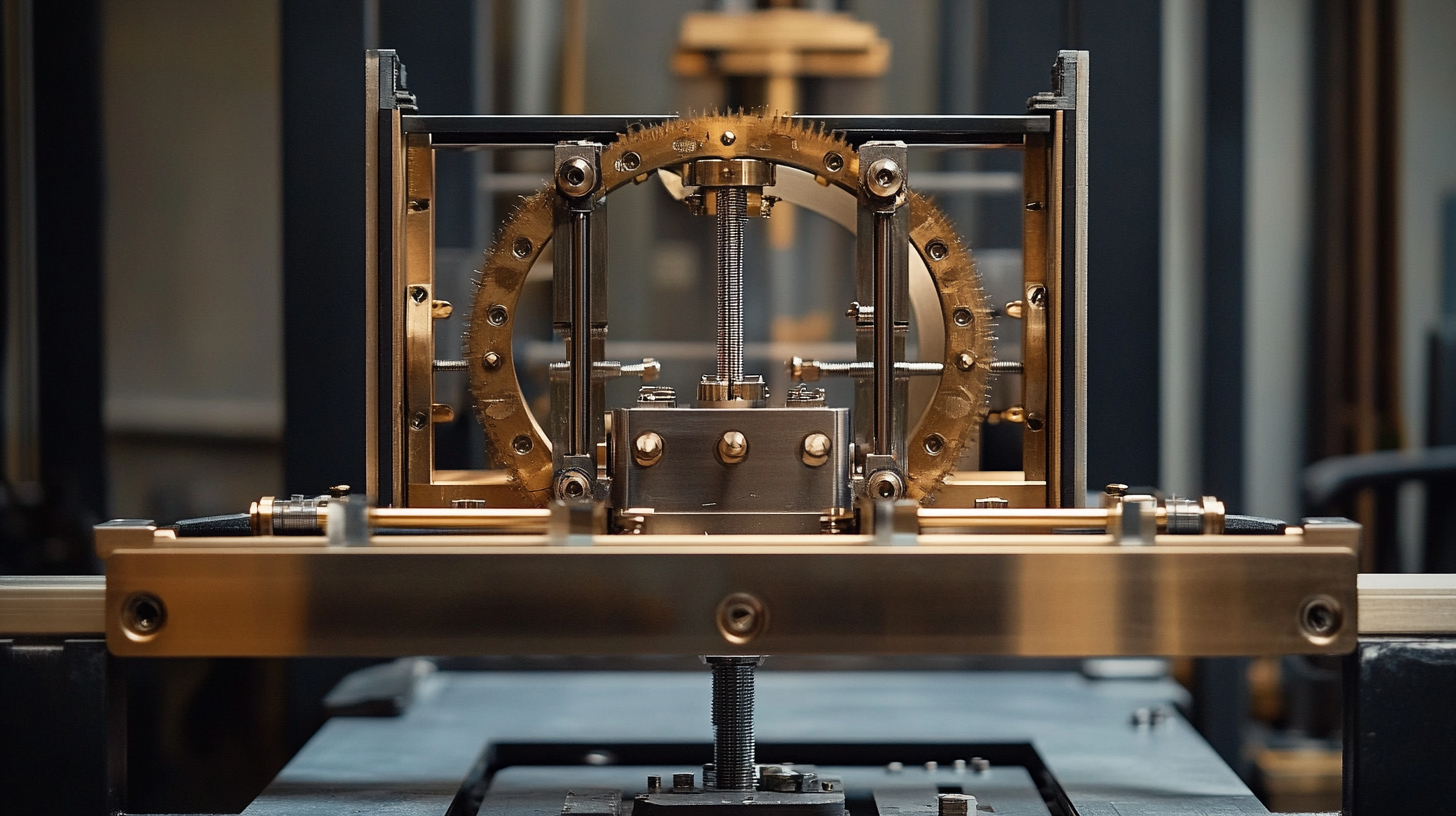

Understanding the Basics of Frame Assembly Machines: A Buyer’s Guide

When it comes to frame assembly machines, buyers must grasp the essential features and specifications that govern these devices' performance and efficiency. Understanding the intricacies of frame assembly is pivotal for businesses looking to streamline their production processes. These machines, often employed in industries ranging from automotive to consumer goods, play a crucial role in enhancing productivity and ensuring quality control. Recent market research by Smith and Associates indicates that the demand for frame assembly machines is projected to rise by 6.5% annually, reflecting their increasing importance in modern manufacturing. Key components to consider when evaluating frame assembly machines include cycle time, integration capabilities, and maintenance requirements. Cycle time, often cited as a critical metric, can significantly impact a company's output. For instance, a machine with a cycle time of under 1.5 seconds may enhance efficiency by up to 30%, according to a report from Manufacturing Insights. Integration capabilities with existing systems also matter; machines that can seamlessly connect with CAD and ERP software afford businesses greater flexibility and production accuracy. Moreover, understanding maintenance needs is vital for maximizing the lifespan of frame assembly machines. Reports suggest that machines requiring less frequent maintenance can save companies an average of $20,000 per year in downtime costs. By investing in modern machines with lower maintenance profiles, businesses not only foster greater productivity but also enhance their overall operational efficiency. By arming themselves with comprehensive insights into these machines, buyers can make informed decisions that will lead to improved performance and productivity in their manufacturing processes.

Key Features to Look for When Selecting Frame Assembly Machines

When selecting frame assembly machines, global buyers should focus on several key features that can significantly impact efficiency and productivity. One of the most crucial aspects is automation capability. According to a recent industry report, automated frame assembly machines can increase production rates by up to 40%, reducing labor costs and human error. This efficiency is essential for manufacturers looking to meet rising global demands while keeping budgets in check.

Another important feature is the machine’s versatility. Buyers should consider whether the machine can handle various frame sizes and materials. A flexible assembly machine can adapt to different product lines, minimizing downtime and setup costs. Research indicates that adaptable machines are becoming increasingly sought after, with a market growth rate of 5.2% annually, as companies aim to remain competitive in a fast-evolving market landscape.

Additionally, the integration of advanced technology such as IoT (Internet of Things) can offer significant advantages. These machines can provide real-time data analytics, improving operational oversight and predictive maintenance, thus preventing costly breakdowns. Industry analysts predict that the IoT market in manufacturing will reach $400 billion by 2025, underscoring the importance of investing in smart technologies for future-proofing operations.

Finally, safety features should not be overlooked. With the potential for workplace accidents, investing in machines equipped with enhanced safety protocols is vital. Reports show that companies prioritizing safety in their machinery experience a 30% reduction in workplace incidents, promoting a healthier work environment. A thorough assessment of these critical factors can ensure that global buyers make informed decisions when selecting frame assembly machines.

Evaluating the Cost-Effectiveness of Frame Assembly Solutions

In today’s competitive manufacturing landscape, the cost-effectiveness of frame assembly solutions is a critical consideration for global buyers. According to recent industry reports, the frame assembly machinery market is projected to grow at a CAGR of 5.4% from 2023 to 2030, driven by the increasing demand for efficient production processes and high-quality end products. With manufacturers constantly striving to reduce overhead while enhancing productivity, evaluating the long-term cost implications of frame assembly machines becomes essential.

The initial investment in frame assembly machines can vary significantly based on technology, complexity, and brand reputation. A 2022 report from MarketsandMarkets indicates that high-tech automated assembly machines can range from $50,000 to over $500,000. However, when considering factors such as labor savings, maintenance costs, and production efficiency, companies may find that these advanced systems lead to lower operational costs over time. For instance, studies show that automating assembly processes can reduce labor costs by up to 30%, making a compelling case for businesses to adopt high-efficiency solutions.

Furthermore, the integration of Industry 4.0 technologies into frame assembly lines has shown promise in boosting cost-effectiveness. Data from McKinsey suggests that smart factories can achieve productivity increases of up to 20% by leveraging real-time data and analytics. This shift not only enhances operational efficiencies but also delivers better quality control, ultimately leading to reduced waste and lower overall production costs. As global buyers evaluate their frame assembly needs, understanding these dynamics will be crucial for making informed investment decisions that align with their long-term goals.

Global Market Trends and Innovations in Frame Assembly Technology

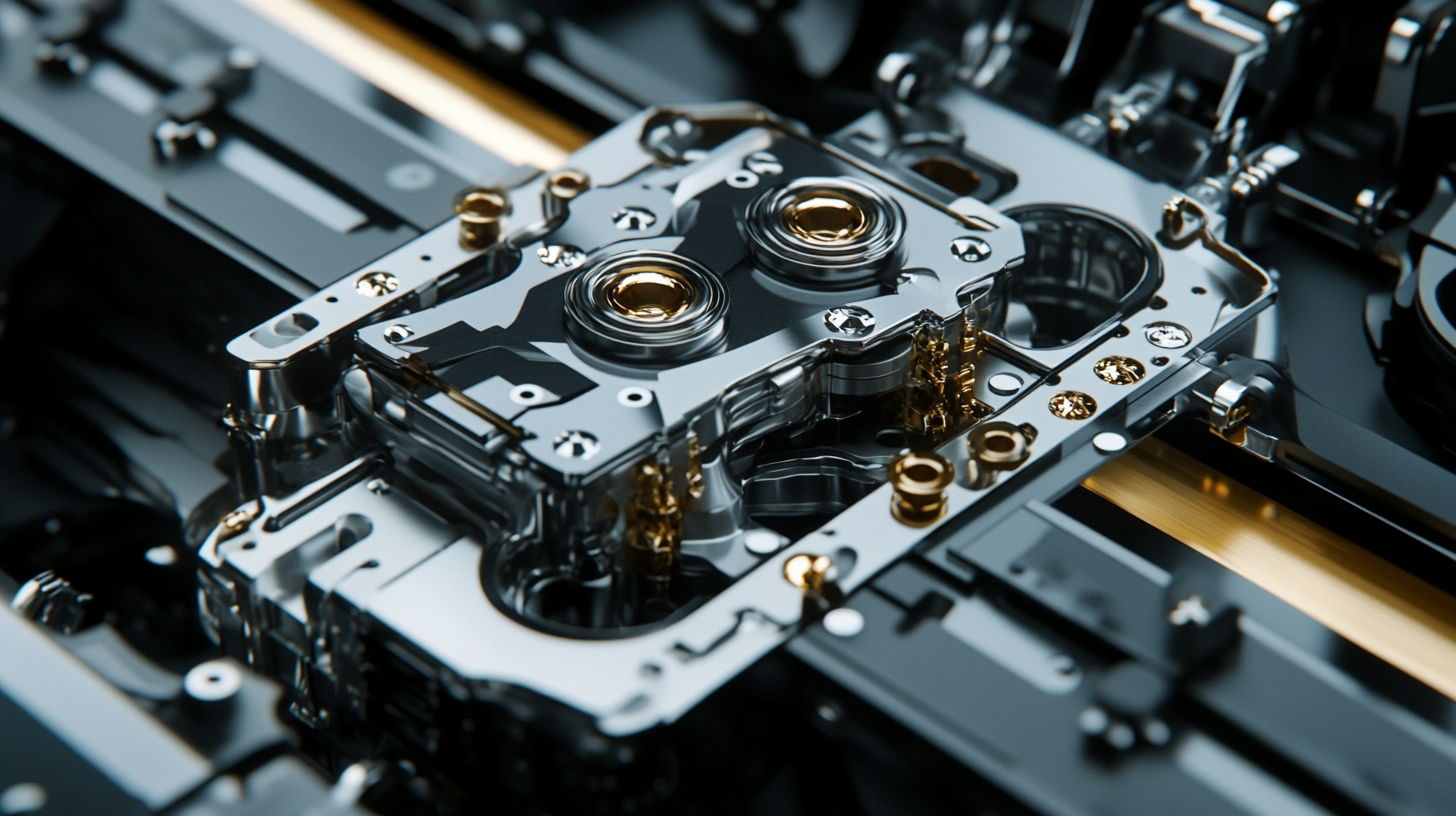

In the rapidly evolving world of manufacturing, frame assembly technology stands at the forefront of innovation, offering a glimpse into the future of production efficiency. Global market trends indicate a significant shift towards automation and smart manufacturing, where frame assembly machines are becoming integral for enhancing productivity. These machines not only streamline the assembly process but also ensure precision and consistency, which are vital for high-quality output in various industries, from automotive to electronics.

The latest advancements in frame assembly technology include the integration of artificial intelligence and IoT (Internet of Things) capabilities. This allows for real-time monitoring and data analysis, helping manufacturers to predict maintenance needs and reduce downtime. Additionally, manufacturers are increasingly adopting modular designs in frame assembly machines, providing the flexibility to adapt to different production needs without significant investment in new equipment. With sustainability becoming a key focus, many companies are also innovating by incorporating eco-friendly practices and materials into their frame assembly processes.

As global buyers seek effective solutions to enhance their manufacturing capabilities, understanding these trends and innovations in frame assembly technology is crucial. The ability to leverage advanced technologies not only sets companies apart from their competitors but also paves the way for long-term growth and sustainability in an ever-competitive market.

Best Practices for Maintenance and Support of Frame Assembly Machines

Maintaining frame assembly machines is crucial for ensuring operational efficiency and minimizing downtime. Regular maintenance practices should be integrated into the workflow, focusing on preventive rather than reactive measures. Establishing a routine maintenance schedule helps in identifying potential issues before they escalate into major problems, ensuring that machinery operates at peak performance. This includes regular inspections, lubrication of moving parts, and the replacement of worn-out components to reduce the risk of unexpected failures.

In addition to routine maintenance, having a robust support system in place is essential. This can be achieved by training staff on proper operation techniques and troubleshooting common issues. Furthermore, collaborating with manufacturers or service providers for expert support can enhance the longevity of the machines. Investing in training not only empowers employees but also significantly reduces repair costs and downtime.

Documenting maintenance activities and machine performance can also provide valuable insights into operational efficiency. By keeping detailed records, companies can analyze trends and make informed decisions regarding upgrades or replacements. Ultimately, a proactive approach to maintenance and support can extend the lifespan of frame assembly machines, ensuring reliable and efficient production processes in today's competitive market.