How to Select the Right Stainless Steel Wire Mesh for Your Needs?

Selecting the right stainless steel wire mesh can be a daunting task. It is critical to understand your specific needs. As industry expert John Smith once stated, "Choosing the right stainless steel wire mesh is vital for optimal performance." This advice is worth considering.

stainless steel wire mesh serves various purposes, from filtration to security. Different mesh sizes and grades exist. Without the right selection, you might face inefficiencies. For example, a mesh with too large openings can compromise filtration. Conversely, a mesh that is too fine may restrict airflow.

Many users often overlook crucial factors like corrosion resistance and wire diameter. These elements play a significant role in the durability of the mesh. Reflecting on your requirements is essential. Even experienced professionals sometimes miss vital details. Take the time to evaluate and choose wisely.

Understanding Different Types of Stainless Steel Wire Mesh Available

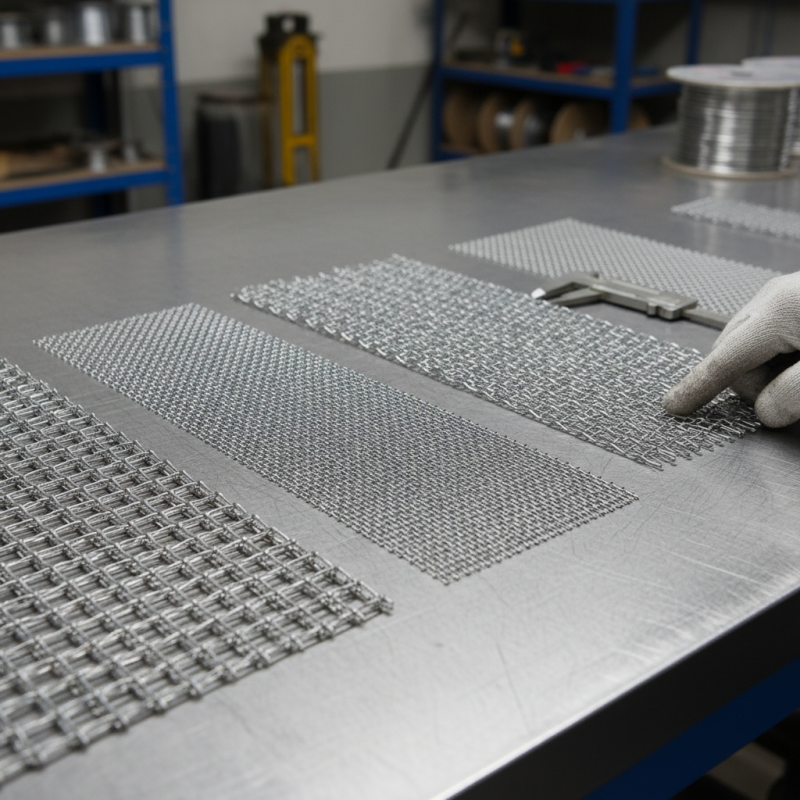

When selecting the right stainless steel wire mesh, understanding the different types available is crucial. There are several varieties, each tailored for specific applications. For instance, welded wire mesh is strong and offers excellent structural integrity. It's commonly used in construction and industrial settings. The uniformity of the openings is a significant advantage, though it can be limited in terms of flexibility.

On the other hand, woven wire mesh provides more versatility. It is available in different weaves, like plain and twill. Each weave offers unique characteristics. The plain weave is often used for filtration systems, while twill weave is more durable and flexible. However, the choice can feel overwhelming. Not considering factors such as wire thickness and mesh size can lead to poor performance in the intended application.

Also, some applications might require specific material grades. For example, marine environments often demand higher corrosion resistance. Making the right choice can be tricky. What works in one scenario may not fit another. Users should think critically about their needs and environmental factors before making a selection. It's vital to ask questions, as this can clarify the best options available.

Comparison of Strengths of Different Types of Stainless Steel Wire Mesh

This bar chart illustrates the tensile strength of various types of stainless steel wire mesh. Selecting the right type based on strength requirements is crucial for specific applications.

Evaluating Wire Mesh Specifications: Gauge, Mesh Count, and Open Area

When selecting stainless steel wire mesh, understanding specifications is crucial. Gauge refers to the thickness of the wire. A lower gauge means a thicker wire. For example, 10-gauge wire is thicker than 20-gauge wire. This directly impacts durability and load-bearing capacity. According to industry standards, a 304 stainless steel mesh with a 10-gauge wire offers high strength, making it suitable for heavy-duty applications.

Mesh count indicates how many openings exist per linear inch. A higher mesh count means smaller openings. For instance, 200 mesh means there are 200 openings within an inch. This is essential for applications needing fine filtration, such as in food processing or pharmaceuticals. Many professionals recommend analyzing the specific requirements for particle size retention, often suggesting a mesh count evaluation alongside project needs.

Open area is another vital metric. It determines the percentage of the mesh that is open space, impacting flow rates and strength. A mesh with 70% open area allows more fluid to pass through, making it ideal for filters. However, mesh with lower open areas may be stronger but permit less flow. Finding the right balance is crucial. Always revisit your specific application needs. Balancing strength, flow, and filtration can be tricky but worth it when selecting wire mesh for different uses.

Identifying the Desired Applications and Industry Standards for Wire Mesh

When selecting the right stainless steel wire mesh, consider the application it will serve. Different industries have unique standards and requirements. For example, food production facilities need mesh that meets strict hygiene guidelines. A finer mesh may be necessary to filter unwanted particles effectively. In contrast, construction projects may prioritize strength over fineness. Think about the specific conditions the mesh will face, such as exposure to chemicals or temperature variations.

Safety is another critical factor. Certain applications require compliance with regulatory standards. It’s not just about the mesh’s durability but also its ability to perform in a specific environment. An oversight here can lead to costly mistakes. You might choose a mesh with less corrosion resistance when it’s actually needed. Assessing these needs helps ensure the wire mesh functions properly in practical applications. An awareness of the industry standards simplifies this process significantly.

Factors to Consider: Corrosion Resistance, Strength, and Durability

When selecting stainless steel wire mesh, key factors include corrosion resistance, strength, and durability. Corrosion resistance is crucial for outdoor and marine applications. Look for wires with high nickel and chromium content. This ensures they withstand harsh environments. The right choice protects your investment and extends the lifespan of the mesh.

Strength matters, especially in high-stress settings. Ensure the wire gauge is appropriate for your needs. A thicker gauge provides improved tensile strength. However, this might increase weight and reduce flexibility. Striking a balance is essential. Remember that each application varies. Reflection on this can save time later.

Tips: Test samples in real conditions to see how they hold up. Assess how often you’ll clean the mesh, too. This can influence your choice. Before settling, consult experts if you’re unsure. It’s better to ask than to face regrets later.

Selecting the Right Supplier: Quality Control and Material Certification

When selecting a stainless steel wire mesh supplier, quality control is crucial. A reliable supplier should have well-defined quality control processes. Look for companies that conduct regular inspections and tests on their products. Ensure they have certifications for the materials they use. This guarantees that the wire mesh meets industry standards.

Material certification is another essential factor. Certifications help verify the composition of the stainless steel used. Check if the supplier provides documentation proving the quality of their materials. Always ask questions about their sourcing and processing methods. It is important to know where the materials come from. This transparency reflects the supplier’s commitment to quality.

Be cautious of suppliers who lack clear information. If a company is reluctant to provide certifications, reconsider your options. You deserve clarity and confidence in your choice. Sometimes, suppliers might overpromise on quality. Take your time to conduct research and request samples. Quality assurance should never be overlooked. A thoughtful selection process pays off in the long run.