How to Streamline Your Production Process with Prehung Door Machine

In the competitive landscape of the manufacturing industry, optimizing production processes is crucial for enhancing efficiency and reducing costs. One innovative solution that has gained traction is the use of the Prehung Door Machine. According to a recent industry report by Smithers Pira, the global market for pre-hung doors is expected to grow at a CAGR of 5.3% over the next five years, driven by increased demand in the residential and commercial sectors. By integrating a Prehung Door Machine into their production line, manufacturers can significantly streamline operations, reducing assembly time and minimizing labor costs.

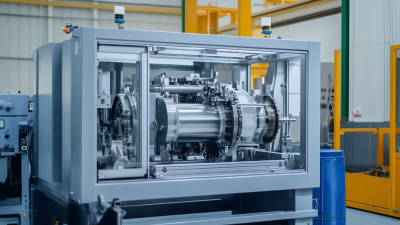

This advanced machinery not only automates the hanging process but also ensures precision, thereby improving product quality and consistency. As businesses seek to adapt to market trends and meet consumer demands, leveraging the capabilities of a Prehung Door Machine is becoming an essential strategy for manufacturers aiming to stay ahead in the industry.

Benefits of Using a Prehung Door Machine in Your Production Line

Using a prehung door machine in your production line can significantly enhance efficiency and quality. According to a report by the Door and Hardware Institute, companies utilizing advanced manufacturing technologies have seen productivity increases of up to 30%. Prehung door machines streamline the assembly process by precutting and preassembling frames and doors, leading to reduced labor costs and shorter lead times. This technology allows for consistent quality and a more uniform product, which is particularly beneficial in large-scale production settings.

Tip 1: Invest in training your workforce on the operation and maintenance of prehung door machines. A well-trained team can maximize the machine's capabilities, ensuring better output quality and reducing downtime.

Another compelling advantage of prehung door machines is the reduction of material waste. The National Association of Home Builders estimates that improved efficiency in production processes could lower waste by 20% or more. By accurately measuring and cutting materials ahead of time, manufacturers can minimize off-cuts and scraps, contributing to environmental sustainability and cost savings.

Tip 2: Regularly perform maintenance checks to keep your prehung door machines running smoothly. Consistency in maintenance can prevent unexpected breakdowns and prolong the life of your equipment, ultimately enhancing production efficiency.

Key Features to Look for in a Quality Prehung Door Machine

When selecting a quality prehung door machine, key features play a pivotal role in enhancing efficiency and ensuring precision in your production process. One of the most crucial aspects is the machine's adaptability to various door sizes and styles. A versatile prehung door machine can handle different materials—wood, fiberglass, or metal—allowing for greater flexibility in production and reducing the need for multiple machines.

Another important feature to consider is automation capabilities. A machine with advanced automation technology can significantly increase output while minimizing human error. Look for machines that offer programmable settings and smart control interfaces, enabling operators to quickly adjust parameters for different jobs. Additionally, pay attention to safety features such as emergency stop buttons and protective guards, which are essential for maintaining a safe working environment.

Lastly, the durability and build quality of the prehung door machine should not be overlooked. Machines constructed from robust materials can withstand the rigors of continuous production and require less maintenance over time. Investing in a well-built machine will not only improve production efficiency but also enhance the longevity of your equipment, ultimately providing a better return on investment.

Step-by-Step Guide to Integrating a Prehung Door Machine into Your Workflow

Integrating a prehung door machine into your workflow can significantly enhance efficiency and productivity in your production process. To begin, assess your current workflow and identify areas where bottlenecks occur. Consider the volume of doors you produce and the resources you currently allocate for assembly and installation. This allows you to determine the right specifications for the prehung door machine that suits your needs.

Next, carefully plan the placement of the machine within your production area to optimize space and workflow. Position the machine close to the assembly line or the area where door components are prepared to minimize the movement of materials. Provide adequate training for your staff, focusing on the operation of the machine, maintenance, and safety procedures. This ensures that your team can maximize the machine's features, reducing errors and increasing output. By systematically incorporating the prehung door machine, you will not only streamline your production process but also improve the overall quality of your final products.

Production Efficiency Before and After Integrating Prehung Door Machine

Common Challenges and Solutions When Using Prehung Door Machines

When integrating prehung door machines into your production process, manufacturers often encounter specific challenges that can hinder efficiency. One widespread issue is the initial setup and calibration of the machines. According to a report from the Door and Window Manufacturing Association (DWMA), improper calibration can lead to a production loss of up to 20% as workers struggle to compensate for misaligned doors. Ensuring that staff are adequately trained in machine operation and maintenance can mitigate these losses and streamline the production line.

Another challenge is managing the diverse dimensions and styles of doors, which can complicate the manufacturing process. A study published in the Journal of Manufacturing Processes highlighted that nearly 30% of production delays are attributed to the need for adjustments when transitioning between different door specifications. To address this, manufacturers can invest in versatile prehung door machines capable of quickly adapting to various sizes and styles without significant downtime. Implementing smart technology that automates these transitions can drastically reduce lead times and improve overall efficiency. By proactively addressing these common challenges, companies can enhance their production workflows and maximize the benefits of prehung door machinery.

How to Streamline Your Production Process with Prehung Door Machine - Common Challenges and Solutions When Using Prehung Door Machines

| Issue Type | Common Challenges | Proposed Solutions | Estimated Impact |

|---|---|---|---|

| Mechanical Malfunction | Frequent breakdowns during operation | Regular maintenance checks and training | Increased uptime and productivity |

| Material Compatibility | Difficulty in handling different door materials | Implement adjustable settings for various materials | Wider range of products can be produced |

| Worker Skill Level | Inconsistent quality due to varying skill levels | Standardized training programs for operators | Improved product consistency and quality |

| Time Management | Inefficiencies in production scheduling | Adoption of lean manufacturing techniques | Reduced lead times and costs |

| Waste Management | High levels of material waste | Implementation of recycling processes | Cost savings and environmental benefits |

Best Practices for Maintaining and Optimizing Your Prehung Door Machine

Maintaining and optimizing your prehung door machine is crucial for enhancing production efficiency and product quality. According to a report by the Woodworking Machinery Industry Association (WMIA), manufacturers that implement regular maintenance schedules can reduce machine downtime by up to 30%. This not only ensures that equipment operates at peak performance but also extends its lifespan, leading to significant long-term cost savings. Regular inspection of key components, such as hinges, casings, and the assembly line settings, can prevent minor issues from escalating into major breakdowns.

In addition to maintenance, optimizing your prehung door machine setup can further streamline your production process. Industry reports indicate that aligning machines for optimal workflow can increase throughput by as much as 25%. Utilizing advanced software for real-time monitoring and adjustments allows for greater control and adaptability in the production line. Furthermore, training staff on the best practices for operating these machines ensures that they can quickly identify and address any inefficiencies, ultimately resulting in higher productivity and improved quality of the finished product.

Related Posts

-

7 Amazing Facts About Used Prehung Door Machinery You Need to Know

-

Unlocking Efficiency: The Ultimate Guide to Door Manufacturing Equipment for Modern Factories

-

Transform Your Production Line: Unleashing the Power of Innovative Casing Machines for Global Manufacturers

-

8 Essential Door Manufacturing Machines to Elevate Your Production Efficiency

-

Unlocking Quality: Essential Tips for Sourcing Premium Best Door Lite Cut Out Machines

-

Resilient Growth of Chinese Door and Jamb Industry Amidst US China Tariff Challenges