Unlocking Efficiency: A Step-by-Step Guide to Operating Casing Machines

In today's competitive manufacturing landscape, maximizing productivity while maintaining high-quality standards is essential for success. One pivotal component in achieving this goal is the effective operation of Casing Machines. These sophisticated pieces of equipment play a crucial role in packaging and protecting products, ensuring they reach their final destinations in optimal condition. However, the efficiency of Casing Machines can vary significantly depending on various factors such as design, operational techniques, and maintenance practices.

In this blog, we will provide a comprehensive step-by-step guide for comparing different types of Casing Machines, highlighting their features, benefits, and potential drawbacks. By understanding these aspects, manufacturers can make informed decisions that enhance their operational efficiency and ultimately drive profitability. Join us as we unlock the secrets to optimizing Casing Machines for your production needs.

Understanding Casing Machines: Types and Applications in Industry

Casing machines play a pivotal role in various industrial sectors, particularly in food and beverage, pharmaceuticals, and chemicals. These machines are designed to automate the process of packaging, ensuring that products are securely encased, which not only enhances shelf life but also maintains product integrity. According to a recent report by Market Research Future, the global packaging machinery market is projected to grow at a CAGR of 4.3% from 2021 to 2027, with casing machines becoming increasingly prevalent due to their efficiency in handling diverse product ranges.

There are several types of casing machines tailored for specific applications, such as horizontal and vertical models, each optimized for different packaging requirements. For instance, horizontal casing machines are commonly utilized in high-speed operations for items like snack foods and dairy products, while vertical machines are favored in the pharmaceuticals sector for their precision and reliability. The versatility of casing machines is reflected in the 2022 Packaging Industry Overview, which noted that about 35% of companies have adopted automated systems to meet rising consumer demands for faster and more reliable packaging solutions. This trend indicates a significant shift towards efficiency, underscoring the essential role of casing machines in modern manufacturing processes.

Key Components of Casing Machines and Their Functionality

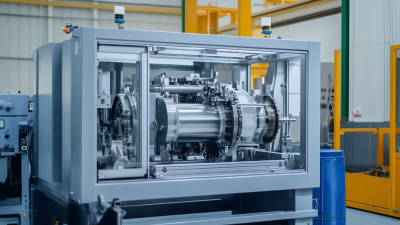

Casing machines play a pivotal role in various manufacturing processes, streamlining the packaging and production line operations. Understanding the key components of these machines is essential for optimizing their functionality and ensuring efficiency. Central to the operation of casing machines is the casing material, which can vary widely depending on the product being packaged. This material must be durable enough to protect the contents while also being adaptable to different product shapes and sizes.

Another critical component is the feeding system, which ensures that materials are consistently and accurately fed into the machine. This system must be calibrated for precision to avoid jams and maintain productivity. Additionally, the sealing mechanisms, which could utilize thermal, adhesive, or mechanical methods, are vital for securely enclosing the products. Each of these components works in concert to enhance the overall efficiency of casing machines, facilitating smoother production processes and ultimately contributing to higher profitability for manufacturers.

Step-by-Step Operation Process for Maximum Efficiency

Operating casing machines efficiently is crucial for optimizing productivity in manufacturing processes. Understanding the step-by-step operation process can make a significant difference in performance. The first step is to familiarize yourself with the machine's components and controls. Before commencing operations, ensure that all parts are well-maintained and that safety protocols are in place. A checklist can be beneficial in confirming that everything is in order, reducing the chances of malfunction during operation.

Once the machine is primed, begin by setting the appropriate parameters tailored to your specific job requirements. This includes selecting the right casing material and adjusting the feed settings to ensure consistent output. Regular monitoring during operation is essential; keeping an eye on the production line will help identify any issues early on, allowing for prompt corrective measures. By following this structured approach, operators can maximize the output quality and efficiency of casing machines, leading to smoother workflows and reduced downtime.

Common Challenges in Operating Casing Machines and Solutions

When operating casing machines, several common challenges can hinder efficiency and productivity. One of the primary issues is improper machine calibration, which can lead to inconsistent casing dimensions and wasted materials. To tackle this problem, it is essential to regularly check and adjust the machine settings according to the specific requirements of each job. This not only ensures accuracy but also helps in maintaining the quality of the output.

Another frequent challenge involves the buildup of debris and residue, which can obstruct the machine's moving parts and lead to malfunctions. Implementing a routine maintenance schedule that includes thorough cleaning can significantly mitigate this issue. Additionally, training operators on proper cleaning protocols and machine handling can increase awareness of potential blockages, thereby enhancing overall machine functionality.

Lastly, human error can contribute to inefficiencies, particularly in monitoring machine performance during operation. To combat this, employing real-time monitoring systems can provide operators with immediate feedback on performance metrics. By addressing these common challenges through proactive maintenance and operator training, businesses can significantly improve the efficiency of their casing machines.

Maintenance Tips to Ensure Longevity of Casing Machines

Casing machines are vital in packaging industries, playing a crucial role in ensuring product integrity and efficiency. However, without proper maintenance, these machines can suffer from downtime and costly repairs. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), regular maintenance can reduce operational downtime by up to 30% and extend the lifespan of equipment by several years. Implementing a scheduled maintenance plan that includes routine inspections, lubrication, and parts replacement can significantly enhance the performance and reliability of casing machines.

One key aspect of maintaining casing machines is to ensure that operators are trained to identify early signs of wear and malfunctions. A study from the International Society for Automation emphasizes that 60% of equipment failures can be attributed to operator errors. By equipping team members with the knowledge to conduct daily checks and understand machine functionalities, organizations can preemptively address issues, reducing the need for extensive repairs. Additionally, keeping a record of maintenance activities can help in tracking performance trends and planning for future upgrades, leading to a more efficient and cost-effective operation.

Unlocking Efficiency: A Step-by-Step Guide to Operating Casing Machines - Maintenance Tips to Ensure Longevity of Casing Machines

| Maintenance Task | Frequency | Estimated Time (Hours) | Tools Required | Notes |

|---|---|---|---|---|

| Inspect machine for wear | Weekly | 1 | Visual inspection tools | Look for rust and damage |

| Lubricate moving parts | Monthly | 0.5 | Lubricant oil, cloth | Use manufacturer’s recommended lubricant |

| Replace worn seals | Quarterly | 2 | Seal replacement kit, screwdriver | Ensure proper size of seals |

| Check electrical connections | Biannual | 1.5 | Multimeter, screwdrivers | Ensure no loose wires |

| Clean air filters | Monthly | 0.5 | Air compressor, vacuum | Replace filters if damaged |

Related Posts

-

Transform Your Production Line: Unleashing the Power of Innovative Casing Machines for Global Manufacturers

-

Unlocking Efficiency with the Best Casing Machines and Their Impact on Production Metrics

-

Comprehensive Insights for Sourcing Prehung Door Machines Globally

-

Unlocking Quality: Essential Tips for Sourcing Premium Best Door Lite Cut Out Machines

-

Understanding the Technical Specifications of Door Assembly Machines for Optimal Procurement Decisions

-

8 Essential Door Manufacturing Machines to Elevate Your Production Efficiency